- Welcome to CableDataSheet, Cable and Wire Technical Consulting Service.

Recent posts

#51

General Cable Information / Re: Cord Designations UL 62

Last post by tacettin - April 11, 2023, 05:12:31 PMSOOW Product Description

The SOOW is the most popular of the portable cord category. These cables are constructed with a flexible rubber jacket, which is reliable for its resistance to abrasion and heat. The last major benefit to this construction is its cost-effectiveness.

SOOW Construction

S for Service

OO for Oil-resistant insulation and Oil-resistant jacket

W for Weather and Water resistance.

Rated to: 600 Volts

Temp. Range: -40 to 90ºC

Size: 18 to 2 AWG

Conductors: 2 to 40 Conductors

SEOOW Product Description

The SEOOW is slightly different from the other portable cables as this construction is made with a thermoplastic elastomer jacket. The biggest difference between this cable and other similar constructions is the additional chemical resistance and the rubber's additional flexible properties.

In more generic terms, Sycor's SEOOW is an engineered, high-quality flexible cord, while other similar constructions are much stiffer. The SEOOW is more resistant to water than SOOW, and it has the largest temperature from –50ºC to 105ºC.

SEOOW Construction

S for Service

E for Thermoplastic Elastomer

OO for Oil-resistant insulation and Oil-resistant jacket

W for Weather and Water resistance.

Rated to: 600 Volts

Temp. Range: -50 to 105ºC

Size: 18 to 2 AWG

Conductors: 2 to 5 Conductors

STOOW Product Description

The various constructions of the STOOW have similar resistance properties as the SOOW and the SEOOW, but not to the same extent. The main difference in this construction can be identified in the name S(T)OOW. The T stands for Thermoplastic, which actually makes the cable significantly less flexible. The STOOW construction is a reliable cable for consumer applications, portable power and lighting extensions when flexibility isn't essential.

STOOW Construction

S for Service

T for Thermoplastic

O for Oil-resistant jacket

W for Weather and Water resistance.

Rated to: 600 Volts

Temp. Range: -40ºC to 60ºC

Size: 18 to 10 AWG

Conductors: 2 to 4 Conductors

The portable and power cabling category has a wide range of constructions that are used for a variety of different industries and applications. The SOOW, SEOOW and STOOW, are very similar products that are relied on by hundreds of unique applications worldwide. With a variety of different constructions, voltage ratings and temperature ratings available, the portable power cord category has one of the widest selections of products available. Sycor is a stocking distributor of all current power cord products and has the ability to track down any obscure requests your team may have.

Source: You are not allowed to view links. Register or Login

The SOOW is the most popular of the portable cord category. These cables are constructed with a flexible rubber jacket, which is reliable for its resistance to abrasion and heat. The last major benefit to this construction is its cost-effectiveness.

SOOW Construction

S for Service

OO for Oil-resistant insulation and Oil-resistant jacket

W for Weather and Water resistance.

Rated to: 600 Volts

Temp. Range: -40 to 90ºC

Size: 18 to 2 AWG

Conductors: 2 to 40 Conductors

SEOOW Product Description

The SEOOW is slightly different from the other portable cables as this construction is made with a thermoplastic elastomer jacket. The biggest difference between this cable and other similar constructions is the additional chemical resistance and the rubber's additional flexible properties.

In more generic terms, Sycor's SEOOW is an engineered, high-quality flexible cord, while other similar constructions are much stiffer. The SEOOW is more resistant to water than SOOW, and it has the largest temperature from –50ºC to 105ºC.

SEOOW Construction

S for Service

E for Thermoplastic Elastomer

OO for Oil-resistant insulation and Oil-resistant jacket

W for Weather and Water resistance.

Rated to: 600 Volts

Temp. Range: -50 to 105ºC

Size: 18 to 2 AWG

Conductors: 2 to 5 Conductors

STOOW Product Description

The various constructions of the STOOW have similar resistance properties as the SOOW and the SEOOW, but not to the same extent. The main difference in this construction can be identified in the name S(T)OOW. The T stands for Thermoplastic, which actually makes the cable significantly less flexible. The STOOW construction is a reliable cable for consumer applications, portable power and lighting extensions when flexibility isn't essential.

STOOW Construction

S for Service

T for Thermoplastic

O for Oil-resistant jacket

W for Weather and Water resistance.

Rated to: 600 Volts

Temp. Range: -40ºC to 60ºC

Size: 18 to 10 AWG

Conductors: 2 to 4 Conductors

The portable and power cabling category has a wide range of constructions that are used for a variety of different industries and applications. The SOOW, SEOOW and STOOW, are very similar products that are relied on by hundreds of unique applications worldwide. With a variety of different constructions, voltage ratings and temperature ratings available, the portable power cord category has one of the widest selections of products available. Sycor is a stocking distributor of all current power cord products and has the ability to track down any obscure requests your team may have.

Source: You are not allowed to view links. Register or Login

#52

Turkey (236) / Infoks Kablo Sanayi ve Tic. Lt...

Last post by tacettin - April 06, 2023, 01:35:25 PM

Infoks Kablo Sanayi ve Tic. Ltd. Şti.

Infoks Cable Limited Company , has been established in Istanbul, 2006. We aim to serve the optical fiber infrastucture of our country and the countries abroad that are continuesly improving in terms of communication.

Infoks is one of the leading firms producing the Tight Buffer Fiber Optic Cables in Turkey.

Our product range specifically covers several types of FTTA, FTTH, Distribution, Breakout, Patch and Industrial Fiber Optic cables that are appropriate for direct termination, distribution and indoor fiber optic cable infrastructure.

One of our most importand stregths is to design and manufacture special and unique cables that are in complience with different specs and standards and are tailor made according to the specific needs and requirements of our customers.

Our company has started its manufacturing activity in year 2007 and focused more on export sales from year 2013 onwards. Since then, INFOKS has been increasing its export capacity and thus achieving its goals for sales revenues. This achievement in goals has been helping INFOKS to improve its technical capabilities in terms of product range and production capacity.

Being a ISO 9001, ISO 14001 and OHSAS 18001 certified company, since Quality is a top priority for INFOKS, we always prefer the highest quality materials from the best raw material suppliers. Meeting the international standards in production and testing is a company policy that we are strongly tied.

Our staff with over 20-years of experience in Fiber Optic Industry are dedicated to build a product line which is a mark of our brand's quality and reputation.

Consequently, we aim to design and produce cables that maximize the customer satisfaction while we are striving to contribute to a society where every citizen has access to a fast, reliable and high quality communications network from wherever they live and work.

Understanding the importance of continues learning and improvement and taking it as a cornerstone, INFOKS has combined the wisdom and experience of the past with contemporary knowledge and technology to be The Reflection of Light, if not the source...

CONTACT

Address : Marmara Geri Dönüşümcüler Toplu İşyeri Koop. Şekerpınar Mah. Defne Sok. No:29 Çayırova Kocaeli / TÜRKİYE

Phone : +90 262 658 2621<br

Fax : +90 262 658 1387

Source : You are not allowed to view links. Register or Login

#53

Turkey (236) / Erat Telekomünikasyon San. Ve ...

Last post by tacettin - April 04, 2023, 12:52:35 PM

Erat Telekomünikasyon San. Ve Tic Ltd. Şti

CORPORATE

Erat in 1998 under the name of Telecom fiber optic cable assemblies, additional installation, fiber optic connectors and all kinds of equipment in the production of fiber optic accessories began to serve.

Assets that form the basis of making additional investments in technology and fiber optics fiber optic interconnection accessories in the areas of production in low-cost high quality manufacturing facility was acquired in 2005. Its mission and vision, principles always our company adopted soon Turk Telekom, Turksat, Botas, Teiaş, Tellcom, SUPERONLINE, Vodafone, Avea as an industry pioneer firms directly or indirectly serves.

Erat Telecom offer the services as well as fiber optic assembly and test areas used Fujikura Fusion Splice fiber optic splice machine, Yokogawa, JDSU, Anritsu OTDR - Power Meter equipment to customers supplied, but these areas of technical training.

Watching the developing world's changing approach to service quality, time, data security policies that we have such a professional team and we are continuing with the equipment as a pioneer in the industry.

MISSION AND VISION

Our Mission,

We provide all services and products to ensure customer satisfaction, quality and standards in the industry to be decisive.

Our Vision,

Our products, our services, after sales support and customer satisfaction follow our policies preferred to be a company in Turkey and the world, in parallel with developing technology to constantly renew at the quality of products and services. Without compromising the quality of our customers to bring the right product at the right price.

HUMAN RESOURCE

Erat Telecom; Since the establishment of competitive advantage is rapidly evolving and changing, invested with the power of the brain is aware obtained. Excellence in all activities and increasing the value of high performance and development has been identified as the main principle.

Excellence in all activities and increasing the value of high performance and development has been identified as the main principle. We age, gender, nationality, race, ethnicity, religion, political approach and the provision of equal employment opportunities regardless of physical condition sincerely believe in the necessity.

This policy; Our group of job recruitment and placement, promotion, change of status from employee wages and other benefits related to the education of several applications until the election is valid for all phases of our business lives. Considering the moral and material rights of our employees to share information on individual and corporate values; Qualified, to ensure a peaceful and warm working environment is our main purpose.

Our Company; have the knowledge, the use of technological systems and produce original products through national production sector has taken its rightful place. For our employees, transparent and equitable management policy of the company by their commitment to prioritize and development that we have the brain power to maintain basic criteria that there bilincindeyiz.hedefi our consistently high, keeping it operates in the sectors leading building will maintain its differences by creating a permanent rule, it supplies become a global brand, and this success to share with all our employees are our basic principles .

its way to becoming a global brand; improving employee motivation of all our employees to ensure equal opportunities, human resources constitute the main pillars of our approach. Human Resources Policy was created with this vision; In line with the Group's strategic plans and objectives to meet the manpower needs of this power in the most efficient evaluation and is intended to ensure continuity. Policy in line; provide training and self-development opportunities for our employees, their productivity by creating career paths that maximize the long way to nourish us in our veins. Erat Telecom; at this point that our company culture and the basic principles to be adopted by all of our employees, especially our all employees, including senior management staff themselves open to continuous learning and development, including tutmalarıdır.baş this policy; All our human resources practices, according to the terms of the day to review, update, and thus a dynamic structure holding the basic policy is to ensure continuous improvement.

Make your job applications fill the form below to send. Do not forget to upload your CV file with your application. Please contact as soon as possible taking into consideration and will be returned to you.

CONTACT INFORMATION

Kayseri Organize Sanayi Bölgesi 22. Cad. No:42 MELİKGAZİ/KAYSERİ

You are not allowed to view links. Register or Login

+90 (352) 322 2770

+90 (352) 330 4041

source: You are not allowed to view links. Register or Login

#54

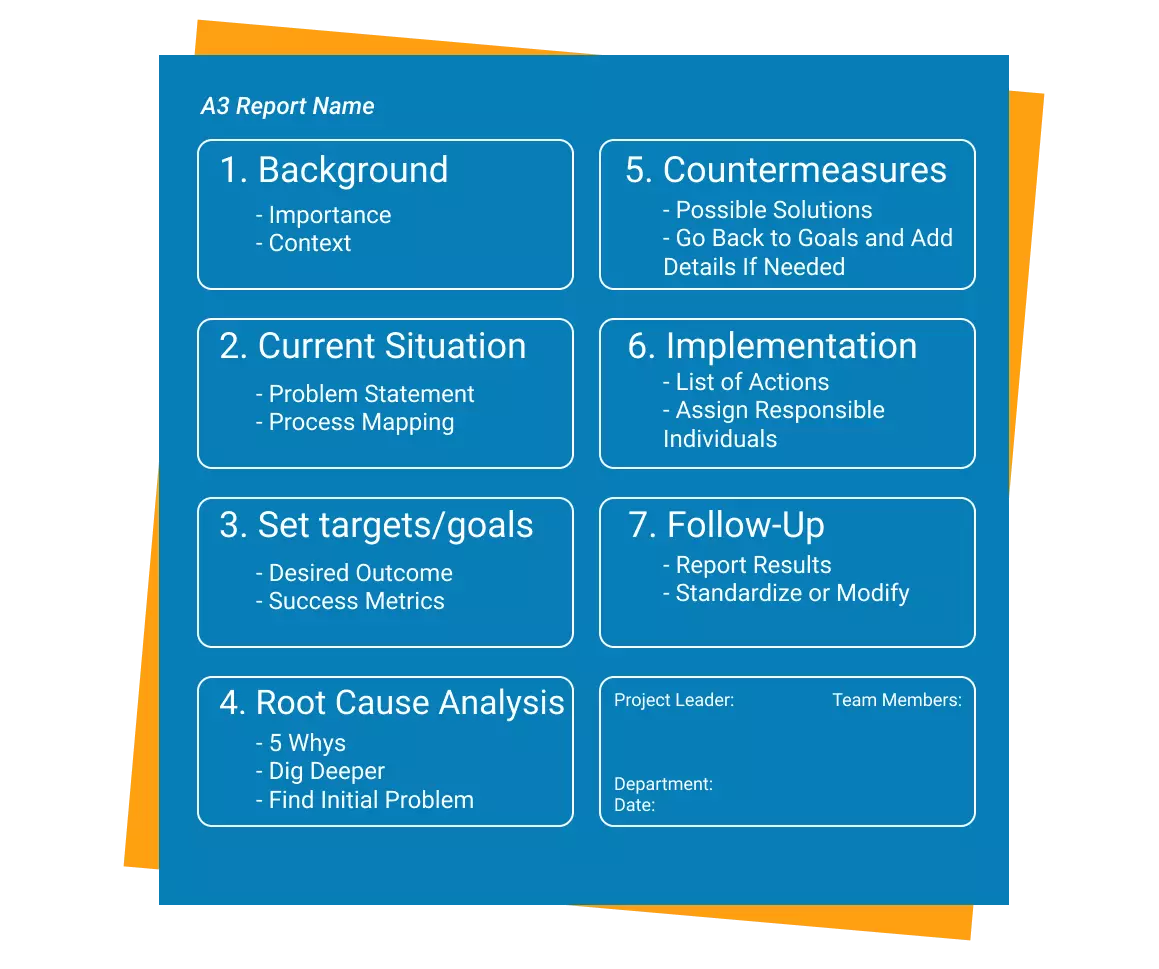

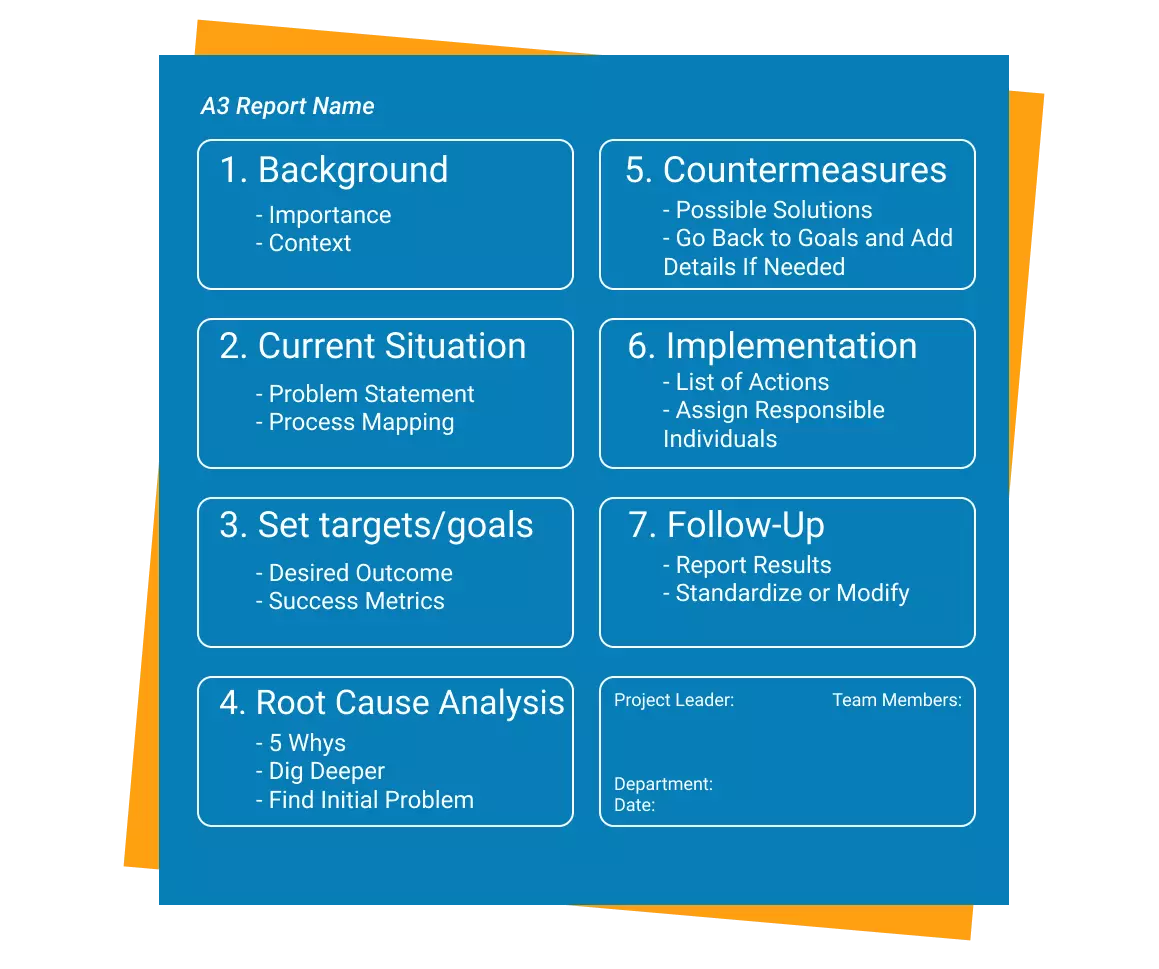

A3 Problem solving method / What is the A3 Problem solving...

Last post by tacettin - April 02, 2023, 01:11:39 AMWhat is the A3 Problem solving method ?

3 problem solving is a structured and collaborative approach to solving business problems. The A3 method takes its name from the size of paper (A3) typically used to document the process. The A3 problem-solving process typically consists of the following steps:

Identify the problem: Clearly define the problem and its impact on the business. This step includes understanding the gap between the current state and the desired future state.

Analyze the problem: Gather data and use root cause analysis tools to understand the cause and effect relationships of the problem. Use the data to develop a hypothesis of the root cause of the problem.

Develop countermeasures: Based on the analysis, develop potential countermeasures to address the root cause of the problem.

Implement countermeasures: Test the proposed solutions and implement the ones that are most effective.

Monitor results: Evaluate the results of the countermeasures and determine if they have effectively addressed the root cause of the problem.

Standardize the solution: Once a solution is found, establish standard work to ensure the solution is maintained and sustained.

The A3 problem-solving technique is a structured and collaborative approach that engages team members to share information and ideas, identify the root cause of the problem, and develop and implement effective solutions. The A3 approach is effective for solving complex problems and enables teams to make data-driven decisions that can lead to lasting improvements in business processes.

3 problem solving is a structured and collaborative approach to solving business problems. The A3 method takes its name from the size of paper (A3) typically used to document the process. The A3 problem-solving process typically consists of the following steps:

Identify the problem: Clearly define the problem and its impact on the business. This step includes understanding the gap between the current state and the desired future state.

Analyze the problem: Gather data and use root cause analysis tools to understand the cause and effect relationships of the problem. Use the data to develop a hypothesis of the root cause of the problem.

Develop countermeasures: Based on the analysis, develop potential countermeasures to address the root cause of the problem.

Implement countermeasures: Test the proposed solutions and implement the ones that are most effective.

Monitor results: Evaluate the results of the countermeasures and determine if they have effectively addressed the root cause of the problem.

Standardize the solution: Once a solution is found, establish standard work to ensure the solution is maintained and sustained.

The A3 problem-solving technique is a structured and collaborative approach that engages team members to share information and ideas, identify the root cause of the problem, and develop and implement effective solutions. The A3 approach is effective for solving complex problems and enables teams to make data-driven decisions that can lead to lasting improvements in business processes.

#55

DMAIC Problem solving method / What is the DMAIC Problem solv...

Last post by tacettin - April 02, 2023, 01:05:35 AMWhat is the DMAIC Problem solving method ?

DMAIC is a problem-solving technique that stands for Define, Measure, Analyze, Improve, and Control. It is a data-driven approach to problem-solving that aims to identify, measure, and eliminate problems in business processes. Here's an overview of the five steps in the DMAIC process:

Define: In this step, you define the problem, its scope, and its impact on the business. You also identify the customer needs and expectations related to the problem.

Measure: This step involves collecting data related to the problem and measuring the current performance of the process. You identify the critical process parameters and measure them to determine the baseline performance.

Analyze: In this step, you analyze the data collected in the previous step to determine the root cause of the problem. You use tools such as cause and effect diagrams, histograms, and statistical analysis to identify the underlying causes of the problem.

Improve: Based on the analysis of the data, you develop and implement solutions to address the root cause of the problem. You may need to test the solutions to ensure their effectiveness.

Control: In the final step, you establish controls to monitor the process and prevent the problem from recurring. You establish performance metrics, put monitoring systems in place, and train personnel to ensure that the improvements are sustained.

The DMAIC approach is commonly used in Six Sigma methodologies, but it can be applied in any business process that requires problem-solving. DMAIC is a systematic approach to problem-solving that helps businesses identify problems, analyze them, and develop solutions that are based on data and evidence.

DMAIC is a problem-solving technique that stands for Define, Measure, Analyze, Improve, and Control. It is a data-driven approach to problem-solving that aims to identify, measure, and eliminate problems in business processes. Here's an overview of the five steps in the DMAIC process:

Define: In this step, you define the problem, its scope, and its impact on the business. You also identify the customer needs and expectations related to the problem.

Measure: This step involves collecting data related to the problem and measuring the current performance of the process. You identify the critical process parameters and measure them to determine the baseline performance.

Analyze: In this step, you analyze the data collected in the previous step to determine the root cause of the problem. You use tools such as cause and effect diagrams, histograms, and statistical analysis to identify the underlying causes of the problem.

Improve: Based on the analysis of the data, you develop and implement solutions to address the root cause of the problem. You may need to test the solutions to ensure their effectiveness.

Control: In the final step, you establish controls to monitor the process and prevent the problem from recurring. You establish performance metrics, put monitoring systems in place, and train personnel to ensure that the improvements are sustained.

The DMAIC approach is commonly used in Six Sigma methodologies, but it can be applied in any business process that requires problem-solving. DMAIC is a systematic approach to problem-solving that helps businesses identify problems, analyze them, and develop solutions that are based on data and evidence.

#56

PDCA Problem solving method / What is the PDCA Problem solvi...

Last post by tacettin - April 02, 2023, 01:00:04 AMWhat is the PDCA Problem solving method ?

PDCA, also known as the Plan-Do-Check-Act cycle, is a cyclic problem-solving technique used to solve problems and improve business processes. Using this technique, you can identify problems, develop solutions, implement those solutions, and evaluate the results. The PDCA cycle consists of the following steps:

Planning: Firstly, you need to identify the problem, determine its causes, and develop solutions. In this step, you can set goals and measurable objectives.

Doing: This is the implementation stage where you put your plan into action.

Checking: To measure the effectiveness of your solutions, you need to evaluate the results. In this step, you check whether you have achieved your goals and what measurable outcomes have been achieved.

Acting: In the final step, you take actions to continually improve the process based on the results and data obtained.

The PDCA method is widely used to increase efficiency in businesses, organizations, and individuals. This method can be applied in various sectors and can help businesses solve problems related to quality control, production efficiency, customer satisfaction, and other business processes.

PDCA, also known as the Plan-Do-Check-Act cycle, is a cyclic problem-solving technique used to solve problems and improve business processes. Using this technique, you can identify problems, develop solutions, implement those solutions, and evaluate the results. The PDCA cycle consists of the following steps:

Planning: Firstly, you need to identify the problem, determine its causes, and develop solutions. In this step, you can set goals and measurable objectives.

Doing: This is the implementation stage where you put your plan into action.

Checking: To measure the effectiveness of your solutions, you need to evaluate the results. In this step, you check whether you have achieved your goals and what measurable outcomes have been achieved.

Acting: In the final step, you take actions to continually improve the process based on the results and data obtained.

The PDCA method is widely used to increase efficiency in businesses, organizations, and individuals. This method can be applied in various sectors and can help businesses solve problems related to quality control, production efficiency, customer satisfaction, and other business processes.

#57

FAQ About Cable / Re: What’s The Difference Betw...

Last post by tacettin - March 25, 2023, 09:16:30 AMPolyether Urethane vs. Polyester Urethane

When it comes to polyurethane, there are two main types: polyether urethane and polyester urethane. Although they are both polyurethanes, each has its own unique set of physical properties that are designed for specific applications. Below is a comparison of polyether and polyester polyurethanes showing lists of properties as well as applications for each material.

Polyester Urethane

In fact, polyesters are typically famous for their superior sliding abrasion resistance. Moreover, one should make an effort your current fortune bestes live caribbean stud poker casino. This makes them excellent for applications where abrasion subjects the polyurethane surface to high levels of friction, such as with chute liners and scraper blades. Typically, this is the main defining attribute when comparing polyesters with other materials. Polyesters are often called the "workhorse" of high abrasion applications and have gained an excellent reputation when used in highly abrasive environments.

Properties:

Excellent Abrasion Resistance

Better Shock Absorption

Higher Tensile Strength

Good Chemical Resistance

Withstand Higher Temperatures Longer

Applications:

Scraper blades

Chute liners

Hopper liners

Wear pads

Snowplow blades

Screening grids

Polyether Urethane

In fact, polyethers are the most common polyurethanes used in the cast elastomer industry. They generally have better dynamic properties than polyesters and are used in wide range of applications such as rollers, bumpers, and bushings. Polyethers tend to make up the majority of polyurethane parts because they are easy to work with and offer more desirable physical properties. Another very interesting thing about polyethers is that they can be tailored with specific additives to perform on the same level or better as polyesters for abrasion resistance. This results in a material that is essentially a hybrid polyether and performs just like a polyester in high scraping abrasion applications.

Properties:

Excellent Dynamic Properties

Hydrolytic Stability

Low-Temperature Flexibility

Good High-Temperature Resistance

UV Resistance

Better Rebound

Applications:

Rollers

High load casters

Skateboard wheels

Body Blocks

Bumpers

Bushings

Coil storage pads

Gears and sprockets

Pulleys

Couplings

source : You are not allowed to view links. Register or Login

When it comes to polyurethane, there are two main types: polyether urethane and polyester urethane. Although they are both polyurethanes, each has its own unique set of physical properties that are designed for specific applications. Below is a comparison of polyether and polyester polyurethanes showing lists of properties as well as applications for each material.

Polyester Urethane

In fact, polyesters are typically famous for their superior sliding abrasion resistance. Moreover, one should make an effort your current fortune bestes live caribbean stud poker casino. This makes them excellent for applications where abrasion subjects the polyurethane surface to high levels of friction, such as with chute liners and scraper blades. Typically, this is the main defining attribute when comparing polyesters with other materials. Polyesters are often called the "workhorse" of high abrasion applications and have gained an excellent reputation when used in highly abrasive environments.

Properties:

Excellent Abrasion Resistance

Better Shock Absorption

Higher Tensile Strength

Good Chemical Resistance

Withstand Higher Temperatures Longer

Applications:

Scraper blades

Chute liners

Hopper liners

Wear pads

Snowplow blades

Screening grids

Polyether Urethane

In fact, polyethers are the most common polyurethanes used in the cast elastomer industry. They generally have better dynamic properties than polyesters and are used in wide range of applications such as rollers, bumpers, and bushings. Polyethers tend to make up the majority of polyurethane parts because they are easy to work with and offer more desirable physical properties. Another very interesting thing about polyethers is that they can be tailored with specific additives to perform on the same level or better as polyesters for abrasion resistance. This results in a material that is essentially a hybrid polyether and performs just like a polyester in high scraping abrasion applications.

Properties:

Excellent Dynamic Properties

Hydrolytic Stability

Low-Temperature Flexibility

Good High-Temperature Resistance

UV Resistance

Better Rebound

Applications:

Rollers

High load casters

Skateboard wheels

Body Blocks

Bumpers

Bushings

Coil storage pads

Gears and sprockets

Pulleys

Couplings

source : You are not allowed to view links. Register or Login

#58

FAQ About Cable / Typical Elastomer Characterist...

Last post by tacettin - March 25, 2023, 09:05:16 AMTypical Elastomer Characteristics

#59

FAQ About Cable / What’s The Difference Between ...

Last post by tacettin - March 25, 2023, 09:02:10 AMWhat's The Difference Between Polyester based PU with Polyether based ?

Polyester based

Oil/solvent resistance

Resistance to weak acids/basics

Abrasion resistance

Excellent mechanical properties

Fungus Resistance

Excellent Vibratory Dampening

Polyester polyurethane is not recommended for use where high humidity or water exposure is a concern. Hydrolysis is a risk which will have a negative effect on the physical properties of the polyurethane.

Polyether based

Low-temperature flexibility

Excellent hydrolytic stability

Food Grade Applications

Temperature resistance

Excellent mechanical properties

Weather (UV) resistance

Polyether polyurethanes are recommended for applications which are expected to experience medium to high stress.

Abrasion Resistance Properties

Without question, the urethanes have outstanding abrasion resistance. They outwear metals, plastics, and other rubbers by a wide margin — often by 8 to 1 or more. Abrasion results from many actions, such as impingement, erosion, impact, scuffing, and sliding.

Sliding refers to scraping and rubbing abrasion. Impingement refers to particles or objects striking the urethane surface at a high angle.

Polyester polyurethane exhibits superior sliding abrasion resistance. This makes it it better suited for applications like scraper blades.

Heat Resistance Properties

Polyurethane elastomers can withstand continuous use up to 194°F (90°C). Flame retardants may be added to the formulation, if required. Both polyester and polyether urethanes perform well at high temperatures. But polyesters are better able to withstand high temperatures longer and are more resistant to heat aging.

Polyethers are less susceptible to dynamic heat build-up.

Low-temperature flexibility

Polyurethane elastomers get harder as temperatures drop. This makes them less flexible and potentially brittle. Depending on the formulation, the brittle point may be between -40°F and -100°F (-40°C and -73°C). Of the two polyurethane types, polyether polyurethane is less affected by cold temperatures.

Polyurethanes can withstand sudden and dramatic temperature drops without cracking. And even at their highest hardness levels, polyurethanes have a better impact resistance than most plastics.

Rebound properties

Some products need to return the energy they absorb (rebound). Polyether polyurethane provides higher rebound than polyester polyurethane.

Shock absorption properties

Sometimes you want the product to absorb the energy it receives (opposite of rebound). In this case, polyester urethane is the better option (e.g. vibration dampening applications).

Hardness Properties

Both polyester polyurethane and polyether polyurethane can be made to any hardness from soft to hard.

Cut and tear resistance

While both polyether and polyester polyurethanes are strong, polyester polyurethanes have a higher tensile strength and a higher cut and tear resistance than polyether polyurethanes.

Water and moisture resistance

Polyether polyurethanes should be selected if the product is to be placed under water or exposed to high humidity as they exhibit excellent hydrolytic stability.

Polyether polyurethanes can be stable in water as warm as 122°F (50°C) for long periods of time. However, they are not recommended for continuous use in water over 158°F (70°C). You can expect .3% to 1% increase in weight due to water absorption and there is a negligible swell in volume.

Polyester polyurethanes are not recommended for applications where water and high humidity is a concern.

Oil and chemical resistance

Polyester polyurethanes are more resistant to exposure to oils, fuels, or chemicals.

source : You are not allowed to view links. Register or Login

Polyester based

Oil/solvent resistance

Resistance to weak acids/basics

Abrasion resistance

Excellent mechanical properties

Fungus Resistance

Excellent Vibratory Dampening

Polyester polyurethane is not recommended for use where high humidity or water exposure is a concern. Hydrolysis is a risk which will have a negative effect on the physical properties of the polyurethane.

Polyether based

Low-temperature flexibility

Excellent hydrolytic stability

Food Grade Applications

Temperature resistance

Excellent mechanical properties

Weather (UV) resistance

Polyether polyurethanes are recommended for applications which are expected to experience medium to high stress.

Abrasion Resistance Properties

Without question, the urethanes have outstanding abrasion resistance. They outwear metals, plastics, and other rubbers by a wide margin — often by 8 to 1 or more. Abrasion results from many actions, such as impingement, erosion, impact, scuffing, and sliding.

Sliding refers to scraping and rubbing abrasion. Impingement refers to particles or objects striking the urethane surface at a high angle.

Polyester polyurethane exhibits superior sliding abrasion resistance. This makes it it better suited for applications like scraper blades.

Heat Resistance Properties

Polyurethane elastomers can withstand continuous use up to 194°F (90°C). Flame retardants may be added to the formulation, if required. Both polyester and polyether urethanes perform well at high temperatures. But polyesters are better able to withstand high temperatures longer and are more resistant to heat aging.

Polyethers are less susceptible to dynamic heat build-up.

Low-temperature flexibility

Polyurethane elastomers get harder as temperatures drop. This makes them less flexible and potentially brittle. Depending on the formulation, the brittle point may be between -40°F and -100°F (-40°C and -73°C). Of the two polyurethane types, polyether polyurethane is less affected by cold temperatures.

Polyurethanes can withstand sudden and dramatic temperature drops without cracking. And even at their highest hardness levels, polyurethanes have a better impact resistance than most plastics.

Rebound properties

Some products need to return the energy they absorb (rebound). Polyether polyurethane provides higher rebound than polyester polyurethane.

Shock absorption properties

Sometimes you want the product to absorb the energy it receives (opposite of rebound). In this case, polyester urethane is the better option (e.g. vibration dampening applications).

Hardness Properties

Both polyester polyurethane and polyether polyurethane can be made to any hardness from soft to hard.

Cut and tear resistance

While both polyether and polyester polyurethanes are strong, polyester polyurethanes have a higher tensile strength and a higher cut and tear resistance than polyether polyurethanes.

Water and moisture resistance

Polyether polyurethanes should be selected if the product is to be placed under water or exposed to high humidity as they exhibit excellent hydrolytic stability.

Polyether polyurethanes can be stable in water as warm as 122°F (50°C) for long periods of time. However, they are not recommended for continuous use in water over 158°F (70°C). You can expect .3% to 1% increase in weight due to water absorption and there is a negligible swell in volume.

Polyester polyurethanes are not recommended for applications where water and high humidity is a concern.

Oil and chemical resistance

Polyester polyurethanes are more resistant to exposure to oils, fuels, or chemicals.

source : You are not allowed to view links. Register or Login

#60